1-Bromooctane: Catalytic Reduction & Wastewater Salt Recovery

Nov 11,2025

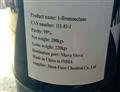

1-Bromooctane (Octylbromide) is a transparent liquid that is produced from a pure bromine source from the Dead Sea. The main application is based on chemical intermediate use, including organic synthesis, e.g. Grignard chemistry. A wide variety of industrial additives can be produced for agrochemicals, coatings and other specialties. The high purity and consistent properties of 1-Bromooctane will allow manufacturing of high quality end-products. The product is available in drums only.

Catalytic reduction of 1-bromooctane by nickel(I) salen

During the past 25 years, electrogenerated nickel(I) salen—a prototypical low valent transition-metal reductant—has been employed for the catalytic cleavage of carbonhalogen bonds in a variety of organic compounds. Pletcher and co-workers generated nickel(I) salen at platinum cathodes in acetonitrile for the catalytic reduction of 1-iodooctane, 1-bromooctane, 2-bromooctane, and 2-bromo-2-methylheptane; products derived via alkyl radical coupling and disproportionation as well as abstraction of a hydrogen atom from the solvent by an alkyl radical were observed. In an effort to avoid or minimize the formation of dialkylmercury compounds, we have briefly explored, in the present work, the catalytic reduction of 1-bromooctane by nickel(I) salen electrogenerated at a mercury cathode in dimethylformamide containing tetramethylammonium tetrafluoroborate. Using cyclic voltammetry (CV) and controlled-potential electrolysis, we have found that the catalytic reduction of 1-bromooctane by nickel(I) salen proceeds smoothly and that four products (n-octane, 1-octene, n-hexadecane, and di-n-octylmercury) are obtained. On the basis of the coulometric n value of essentially 1, we conclude that all of the products arise from catalytically formed n-octyl radicals. Double-potential-step chronocoulometry indicates that neither nickel(II) nor nickel(I) salen is adsorbed onto the mercury electrode.[1]

A cyclic voltammogram obtained at 100 mV s−1 for the reduction of 0.50 mM nickel(II) salen in the presence of 5.0 mM 1-bromooctane in DMF containing 0.10 M TMABF4 is depicted. As anticipated, there is an enhancement in the cathodic peak current due to the catalytic reduction of 1-bromooctane; in addition, there is no anodic current because nickel(I) salen is consumed by the substrate. Following the main cathodic peak at −0.91 V is a small shoulder at −1.00 V; a similar feature has been observed previously in a study of the catalytic reduction of alkyl iodides by nickel(I) salen electrogenerated at a carbon electrode. This shoulder cannot be attributed to the direct, irreversible two-electron reduction of 1-bromooctane at mercury in DMF containing 0.10 M TMABF4, because the peak potential for the latter process is −1.51 V under these conditions. A series of controlled-potential electrolyses was carried out to identify and quantitate the products arising from the catalytic reduction of 1-bromooctane. For all experiments the n value was essentially one, and all of the 1-bromooctane was consumed except for a trace that remained for catalytic reduction of the highest concentration of substrate. Among the four products, the major species are n-hexadecane and n-octane, along with smaller amounts of 1-octene and di-n-octylmercury.

Separation and extraction of NH4Br and (K,NH4)2SO4 from 1-Bromooctane production wastewater

1-Bromooctane is an important organic fine chemical intermediate, mainly used in the synthesis of various surfactants. The production of 1-Bromooctane generates saline wastewater. Since the wastewater contains KBr and H2SO4 and cannot be discharged directly, it is usually treated by chlorine oxidation or hydrogen peroxide oxidation (LI, 2024) to obtain the product bromine. However, the use of the oxidation method has the problems of a large amount of oxidizer input, storage difficulty, and a high amount of waste salt generation. This paper proposes a physical method to separate and recover bromine in the form of salt. A process approach for the salt extraction of wastewater containing bromine has been established in order to separate and acquire (K,NH4)2SO4 and NH4Br. This was done using the dry basis phase diagrams of the quaternary systems K+,NH4+//SO42-,Br-–H2O at 298.15 K and 323.15 K. Experiments were conducted to confirm the viability of the proposed process route for the recovery and separation of brominated salts from wastewater produced during the 1-Bromooctane manufacturing process.[2]

In order to solve the problem of the treatment of bromine-containing wastewater produced by 1-Bromooctane, this paper proposes to separate and extract the bromine resources therein by the crystallization method. Based on the design needs of the new process, the solubility of the quaternary systems K+,NH4+//SO42-,Br-H2O at 298.15 K and 323.15 K was investigated by isothermal dissolution equilibrium method. The composition of the equilibrium solid phase was determined by wet slag method and XRD. Based on the theoretical analysis of the phase diagram of the quaternary system K+,NH4+//SO42-,Br-–H2O, a process route for salt extraction from 1-Bromooctane production wastewater was designed. Using the actual wastewater composition as a starting point, after evaporation and crystallization at 298.15 K, the mother liquor obtained was warmed up to 323.15 K and evaporated and crystallized again to obtain the potassium-ammonium compound fertilizer. At the same time, the mother liquor obtained from the separation was cooled down to 298.15 K to continue evaporation to obtain the product NH4Br. Afterwards, a second cycle is started by blending the halogen

References

[1]Andrea L Guyon . (2002). Catalytic reduction of 1-bromooctane by nickel(I) salen electrogenerated at a mercury cathode in dimethylformamide. Journal of Electroanalytical Chemistry, 526 1, Pages 134-138.

[2]Shuwen Yang. (2024). Separation and extraction of NH4Br and (K,NH4)2SO4 from 1-Bromooctane production wastewater by crystallization method. Chemical Engineering Science, 301, Article 120742.

- Related articles

- Related Qustion

N-Ethylmethylamineserves as a pharmaceutical/fine chemical intermediate, with distinct liquid-vapor adsorption mechanisms on activated carbon.....

Nov 11,2025Chemical MaterialsAsiatic acid protects dopaminergic neurons via NLRP3 inflammasome inhibition, and shows promise in treating neurodegenerative diseases.....

Nov 11,2025Organic Acids1-Bromooctane

111-83-1You may like

- 1-Bromooctane

-

- $0.00 / 100KG

- 2025-11-21

- CAS:111-83-1

- Min. Order: 1KG

- Purity: 99%

- Supply Ability: 1000mt

- 1-Bromooctane

-

- $100.00 / 1KG

- 2025-09-25

- CAS:111-83-1

- Min. Order: 1KG

- Purity: 99%

- Supply Ability: g-kg-tons, free sample is available

- 1-Bromooctane

-

- $0.00 / 1kg

- 2025-06-20

- CAS:111-83-1

- Min. Order: 1kg

- Purity: 0.99

- Supply Ability: 20tons